- Home

- Project Waste

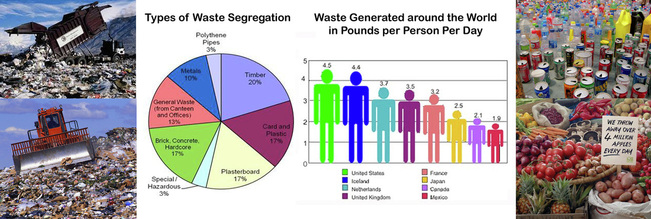

- Statistics

- What's Wasted

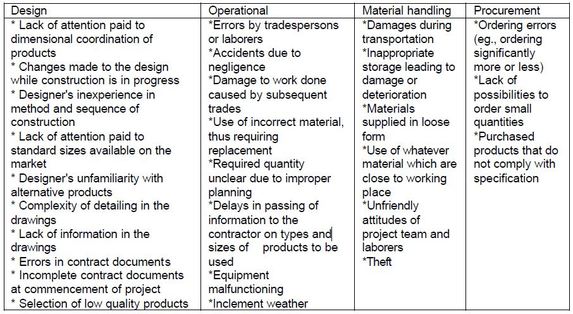

- Why is it Wasted

- Material Lifecycle

- Recycling

- Landfill

- Smart Manufacture

- Design for Disassembly

- Simple Construction

- Avoiding Wasteful Techniques

- Legislation & Policy

- Case Studies

One day the earth's natural resources will run out then what will we do...

Overview

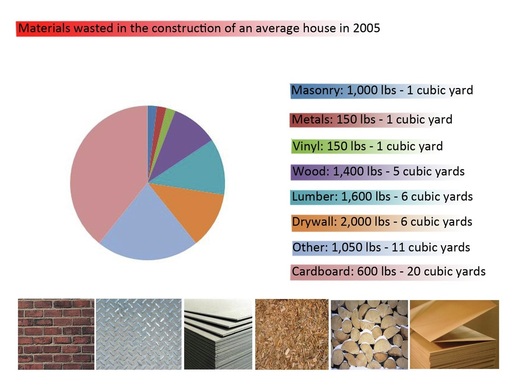

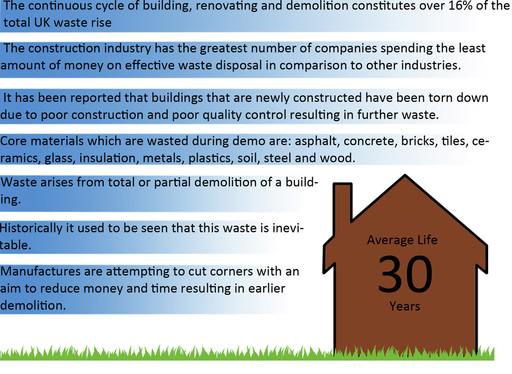

Waste produced from the production, use and demolition of the construction industries six main materials is fast becoming an oversized problem. It has since been noted that the construction industry is responsible for spending the least amount of money in attempting to combat the waste problem in comparison to ALL other industries. This page will highlight the wasted materials and/or components that go into each of the finished products, and will also highlight how the material is wasted while on site.

IT'S A FACT

- The volume of waste produced in an hour in the UK could fill the Albert Hall.

- It is estimated that 90% of what we put in our bins is recoverable.

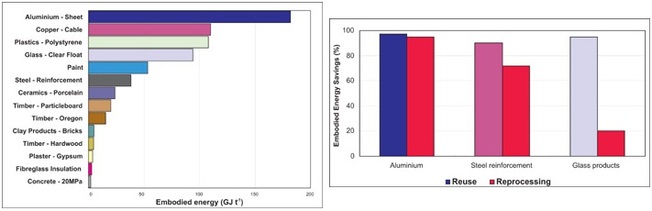

- Producing steel from recycled materials saves around 75% of the energy needed to make steel from raw materials.

- Nearly 3 million tonnes of plastic waste is generated every year in UK alone but only 5% is recycled.

The Materials

To look at the amount wasted affectively, six of the most used and wasted materials used in construction have been chosen these are:BRICK, CONCRETE, TIMBER, STEEL, PLASTICS, GLAZING.

‘Much building waste is made up of materials such as bricks, concrete and wood damaged or unused for various reasons during construction. Observational research has shown that this can be as high as 10 to 15% of the materials that go into a building, a much higher percentage than the 2.5-5% usually assumed by quantity surveyors and the construction industry.’

‘Much building waste is made up of materials such as bricks, concrete and wood damaged or unused for various reasons during construction. Observational research has shown that this can be as high as 10 to 15% of the materials that go into a building, a much higher percentage than the 2.5-5% usually assumed by quantity surveyors and the construction industry.’

BRICK

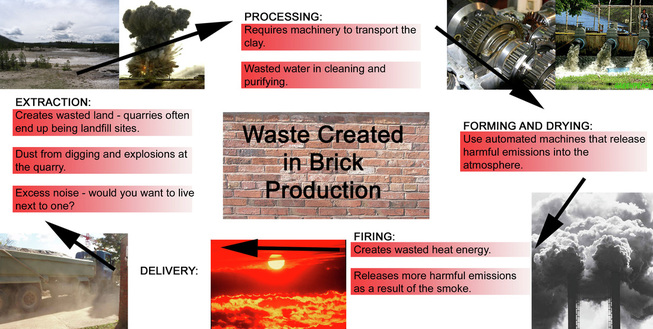

We all recognise brick, most of our homes are made out of them. Yet that hard block we all relate to keeping us safe and secure produces waste in production, construction and demolition. We need to cut down on waste this looks at the current methods we are using and the wastages produced from them.

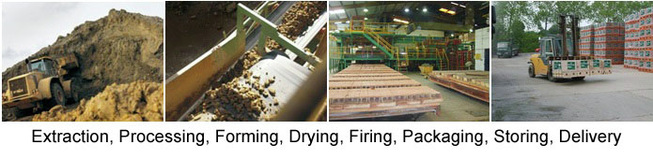

The Production

The Waste From Production

The Positives

Despite the waste, brick is the least wasted material out of the six being talked about. The reasons why:

- Unfired clay is reused and imperfect fired bricks are crushed and used as aggregates within the construction industry.

- Very low embodied energy due to their anticipated life span of 150 years.

- The energy used to produce and deliver brickwork for an average semi detached home is less than 2% of what will be spent heating that home over 150 years.

- Some companies are harvesting their own water in order to prevent water wastages.

- Some companies are using the waste heat from the kiln to help the drying process.

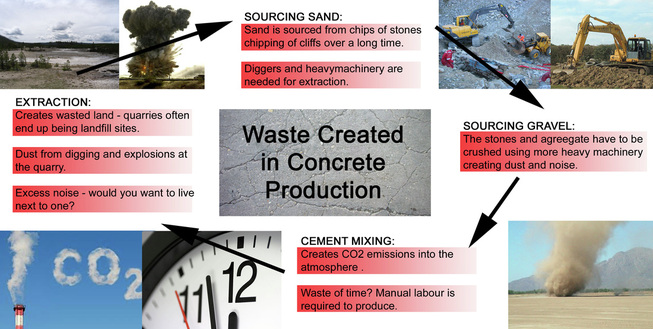

CONCRETE

When we think of concrete we think of heavy duty buildings and pavements. The over use of this material has resulted in it being the most wasted material used in the construction industry.

The Production

The Waste From Production

The Positives

The reasons we continue to use concrete as a long term material:

- Using concrete minimises the depletion of our natural rescources.

- Concrete is an affordable long term building product.

- Concrete is a durable material which actually gains strength over time, it conserves resources by reducing maintenance and the need for reconstruction.

- Concrete is a versatile product.

- Although extracting raw materials from the earth is needed to make the concrete, the environmental impact is far lower.

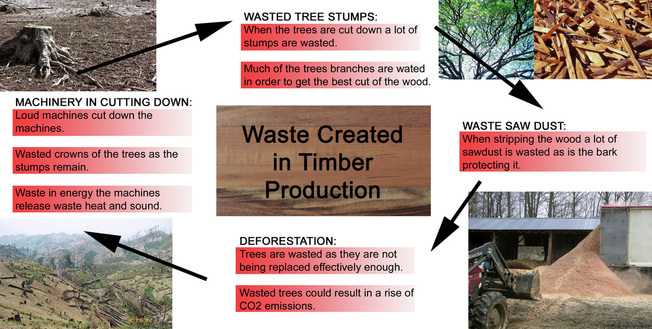

TIMBER:

We use timber in the construction industry particularly in housing. But our trees are being torn down at an unbelievable rate, we need to value our forests as a resource and respect what it provides us with.

The Production

The Wastages From Production

The Positives:

- Timber is seen to be the most sustainable construction material over steel, concrete, masonry and PVU due to it being a renewable source and its limited waste.

- With offsite production of timber building components, waste can be reduced to up to 40%. Within the past 5 years the production of timber framed structures have doubled, but the quantity of waste has remained constant.

- Wasted timber such as off cuts and damaged timber created during the construction process can be cleverly used to form smaller components within the building such as window frames or wooden detailing although the majority is either scrapped or sent away to be recycled.

STEEL:

Steel is seen to big and strong, safe and secure but the damage and waste it can cause in its production is often far larger than anticipated. It is the most used in the construction industry mainly in reinforced concrete design.

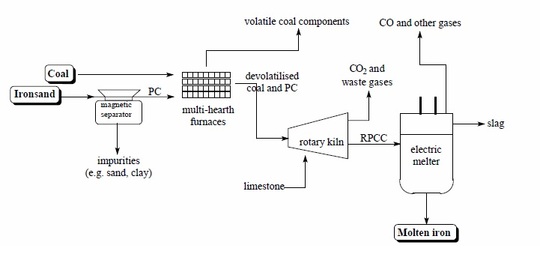

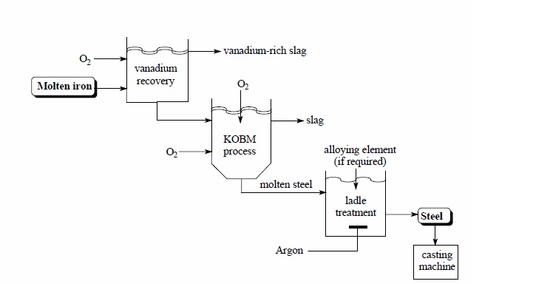

The Production

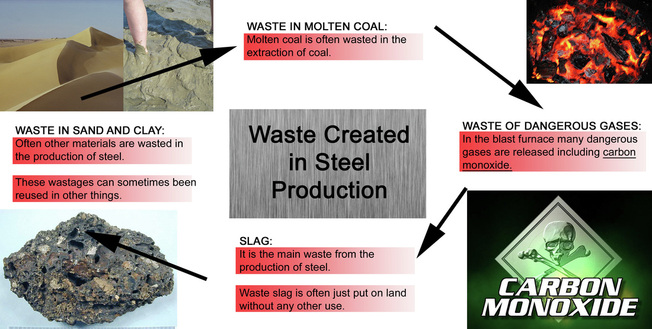

The Wastages From Production

The Positives

- Iron scrap is also another waste product within the steel making industry, which can be now recycled and used for other purposes.

- Due to the on-site production of steel and components for the construction industry, waste on site is very limited unless careless mistakes are made during construction.

- Much of the scrap steel is used from the production process and the construction process due to its high recyclable properties making steel a highly sustainable material in terms of processing waste.

- With value engineering playing a part within the steel construction industry, it helps to reduce the waste on site by eliminating the scope for mistakes being made.

- Value Engineering (Organised approach to providing the necessary functions at the lowest cost)

Widely used within the steel construction industry to keep costs and waste to a minimum by carefully planning and evaluating the function, use of materials and needs within a building project.

The organised approach identifies and eliminates cost and waste through several techniques;

- Preparation

- Information (Functional analysis)

- Analysis

- Creation (Alternative ways of meeting requirements)

- Evaluation (How will each alternative meet required functions, and how great will the savings be)

- Development

- Presentation (Best alternative chosen and presented to client)

- Follow-Up

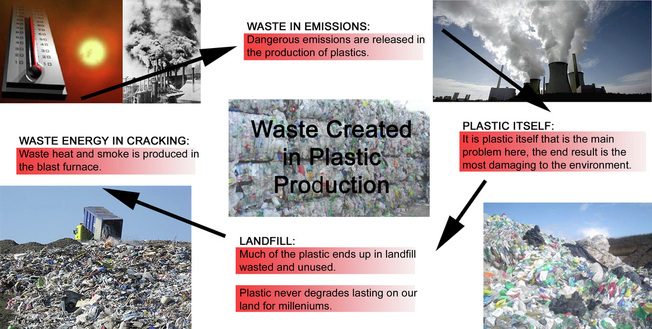

PLASTICS:

Plastics are fast taking over the landfill sites which will lead to more sites being opened in our country, on our land in which we live. It will affect us and our attitude to plastic waste needs to change.

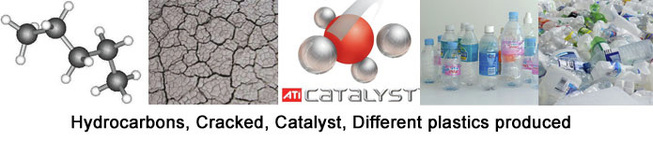

The Production

The Wastages From Production

The Positives

Unfortunately there are very few we need to recycle plastics far more. For more information see Recycling.

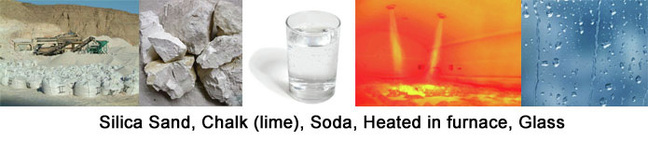

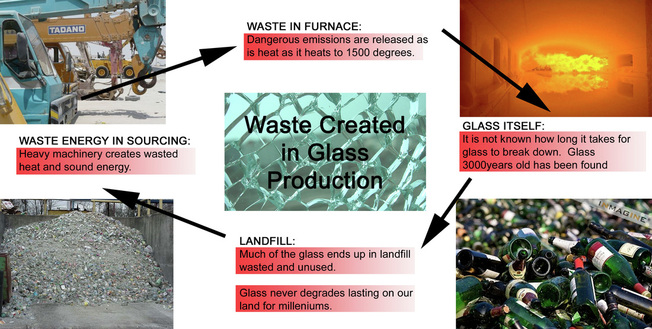

GLAZING:

Glass, glass, glass. What do you think of? Most people think of glass jars and bottles and though the production of them is relevant, the wastages of glazing and glass in the construction industry is the topic of discussion,

The Production

The Wastages From Production

The Positives

- Recycling just 2 glass bottles saves enough energy to boil water for five cups of tea.

- With every tone of waste glass recycled, 1.1 tonnes of virgin material is saved.

- Can you believe that glass recycling in 2003 saved enough energy to launch 10 space shuttle missions?

- Green bottles are made with up to 90% recycled glass content.

- 100% of recycled glass can be used to make new glass bottles and jars, without any loss in quality.