- Home

- Project Waste

- Statistics

- What's Wasted

- Why is it Wasted

- Material Lifecycle

- Recycling

- Landfill

- Smart Manufacture

- Design for Disassembly

- Simple Construction

- Avoiding Wasteful Techniques

- Legislation & Policy

- Case Studies

How simple design can reduce waste of materials in construction...

Overview

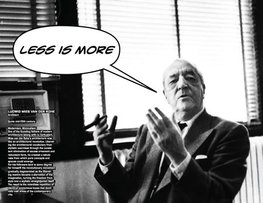

Ludwig Mies van der Rohe

Simple construction refers to ensuring the efficiency and proper utilization and use of resources at all stages of construction. This involves good management which will help in managing the amount of waste that is produced which reduces the environmental impact of construction.

"Architecture that creates maximum effect with a minimum of means. Maximum comfort with minimal energy consumption, maximum functionality with minimal area, maximum quality of life with a minimal expense of resources."

"Architecture that creates maximum effect with a minimum of means. Maximum comfort with minimal energy consumption, maximum functionality with minimal area, maximum quality of life with a minimal expense of resources."

Value Engineering

Value engineering may be broadly defined as an organized approach in identifying unnecessary costs in design and construction and in soliciting or proposing alternative design or construction technology to reduce costs without sacrificing quality or performance requirements. This approach is usually applied at the beginning of the construction phase of the project life cycle.

Sometimes, the fees for design services is tightly monitored.Such a practice in setting specific fees encourages the design professionals to adopt known and tried designs and construction technologies without giving much thought to alternatives that are innovative and sometimes risky. Contractors on the other hand are willing to examine such alternatives especially in the private sector when offered incentives for sharing the savings by owners.This subconsciously or consciously prevents the wastage of materials in the construction planning and construction phase of the project

Sometimes, the fees for design services is tightly monitored.Such a practice in setting specific fees encourages the design professionals to adopt known and tried designs and construction technologies without giving much thought to alternatives that are innovative and sometimes risky. Contractors on the other hand are willing to examine such alternatives especially in the private sector when offered incentives for sharing the savings by owners.This subconsciously or consciously prevents the wastage of materials in the construction planning and construction phase of the project

Construction Planning

- Plan before you buy and also try specifying materials that have good recyclable content as this will help to reduce the carbon footprint of the building.

- Plan your building supplies so as to keep wastage of materials to a minimum.

- Use local suppliers for locally available materials and also for reclaimed and recycled building products.

- Ensure safe and correct storage of materials so as to avoid damage by natural and artificial elements and also to prevent theft.

Construction Phase

- Ensure the appropriate materials are used for specific jobs with the best workmanship so as to avoid rework, as rework cost money and waste time and materials.

- Use local, natural and sustainable materials and construction techniques, and also use renewable and recycled materials for the long term benefit of the environment. This also helps in avoiding waste.

- Avoid using non-compliant, non-standard or inappropriate materials as this can increase cost and wastages.

- Hire specialist contractors to carry out work on the building project that require special skills.

- Materials Exchange Programmes are good ways of exchanging excess and used materials. This can be used by those who have excess or shortage of materials.

Use resources efficiently in construction

Wasting resources such as building materials adds considerable amount to both the environmental and financial cost of construction. Buying materials that you don't use means that you have to pay both the purchase and disposal costs. It makes sense for both main contractors and individual building trades to use resources more efficiently and work together to reduce the environmental impact of their work. Reducing the amount of waste you produce makes it easier to comply with legal control of waste.

On the problem of wastage in the construction industry. You could look deeper into Whats wasted and the reasons Why is it wasted and also ways of Avoiding wasteful techniques. To give yourself a better understanding of the materials that can be reused in the construction industry, refer to the Recycling page for more in depth details.

Sustainability

New Developments:

Environmentally Friendly Concrete

A New Form of an Old Material. Scientists at a British concrete manufacturer, the London-based Novacem, claim to have developed a new form of concrete that effectively absorbs large amounts of carbon dioxide as it hardens. Novacem's new version of concrete, uses a different raw material, magnesium sulphate, which requires much less heating. Novacem claim that each tonne of cement can absorb up to 0.6 tonnes of CO2. This is opposed to figures that claim that each tonne of old style cement emits about 0.4 tonnes of CO2.

For any building material to actually absorb carbon rather than just emit it in its production, is really a breakthrough, though Novacem admit the material is still in its trial period. The consequences of having an environmentally friendly building material available and on the market for builders to use, and for architects and designers to insist on using in the design of buildings and roads, is immense, and a real development for a sector which has been very guilty of creating carbon emissions through building operations.

Novacem state that they estimate that there are around 10,000 billion tonnes of magnesium silicates available worldwide, and that their process could use alternative byproducts as well that also contain forms of magnesium.

The product itself could be several years away from being available to the building public and the building trade in general, but it does have great potential, and is eagerly awaited.

Environmentally Friendly Concrete

A New Form of an Old Material. Scientists at a British concrete manufacturer, the London-based Novacem, claim to have developed a new form of concrete that effectively absorbs large amounts of carbon dioxide as it hardens. Novacem's new version of concrete, uses a different raw material, magnesium sulphate, which requires much less heating. Novacem claim that each tonne of cement can absorb up to 0.6 tonnes of CO2. This is opposed to figures that claim that each tonne of old style cement emits about 0.4 tonnes of CO2.

For any building material to actually absorb carbon rather than just emit it in its production, is really a breakthrough, though Novacem admit the material is still in its trial period. The consequences of having an environmentally friendly building material available and on the market for builders to use, and for architects and designers to insist on using in the design of buildings and roads, is immense, and a real development for a sector which has been very guilty of creating carbon emissions through building operations.

Novacem state that they estimate that there are around 10,000 billion tonnes of magnesium silicates available worldwide, and that their process could use alternative byproducts as well that also contain forms of magnesium.

The product itself could be several years away from being available to the building public and the building trade in general, but it does have great potential, and is eagerly awaited.

Prefabricated Steel Buildings:

However sustainable the material may be, there are still some deficiencies with on-site steel construction. Two main aspects to consider are the length of time that it takes to complete the steel work on a site, and how many workers have to travel to that site every day. On a daily basis, steel workers continue travelling long distances to and from construction sites. On site welding is also necessary to meet structural specifications in the drawings. While it is undeniable that steel is a sustainable material, the deficient aspects of steel are exposed when the on-site construction methods are assessed.

In order to use steel more sustainably, architects and engineers have looked to introduce steel to the prefabricated (prefab) building industry. By doing so, it is possible to harness the benefits of both steel design and prefab construction, while the two cooperatively eliminate traditional inadequate aspects. Prefab buildings cost less from a construction perspective because most of the labor is performed in a factory. The workers only need to travel to and from a static job site, the factory, rather than temporary job sites that are very far away.

With ease in assembly comes ease in disassembly as well. This is a sustainable aspect to steel prefab for many reasons. The lifecycle of a steel prefab home addresses the ‘cradle to cradle’ philosophy. These buildings can be disassembled and recycled while leaving minimal impact on earth beneath it and recycled, or moved elsewhere and reassembled. Also, additions and alterations to these buildings are made easy with the bolted steel frame.

In order to use steel more sustainably, architects and engineers have looked to introduce steel to the prefabricated (prefab) building industry. By doing so, it is possible to harness the benefits of both steel design and prefab construction, while the two cooperatively eliminate traditional inadequate aspects. Prefab buildings cost less from a construction perspective because most of the labor is performed in a factory. The workers only need to travel to and from a static job site, the factory, rather than temporary job sites that are very far away.

With ease in assembly comes ease in disassembly as well. This is a sustainable aspect to steel prefab for many reasons. The lifecycle of a steel prefab home addresses the ‘cradle to cradle’ philosophy. These buildings can be disassembled and recycled while leaving minimal impact on earth beneath it and recycled, or moved elsewhere and reassembled. Also, additions and alterations to these buildings are made easy with the bolted steel frame.

Fly Ash Brick:

Fly ash brick (FAB) is a composite of non-clay materials, a high percentage of which is ash recycled from coal-fired electrical power plants. Brick made from fly ash utilizes a high proportion of recycled content and has very low embodied energy and carbon dioxide emission associated with production, offering a green material choice. Colored brick is achieved by pigmenting with colorfast mineral oxides. The manufacturing method is said to save energy, reduce mercury pollution, and costs 20% less than traditional clay brick manufacturing. Fly ash brick prototypes have achieved embodied energy and CO2 emission levels in the range of 15 to 20 percent that of clay brick, and may drop below 10 percent in full production.The raw material that is used for fly ash brick are:

Fly ash

Sand/Stone dust

Lime

Gypsum

Cement

Fly ash brick testing has determined it is a safe product. It passes by a wide margin in EPA-mandated tests for potentially hazardous materials—landfill simulation and rainwater (acid rain) leaching tests—with no detectable mercury. Although not required by regulatory agencies for construction materials, a dermal exposure test also revealed no detectable mercury levels.

"Simple construction as a whole can best be achieved when contractors and clients use resources more efficiently at every stage of construction in order to reduce the amount of waste produced to the barest minimum."- Kamil Mu'azu

Fly ash

Sand/Stone dust

Lime

Gypsum

Cement

Fly ash brick testing has determined it is a safe product. It passes by a wide margin in EPA-mandated tests for potentially hazardous materials—landfill simulation and rainwater (acid rain) leaching tests—with no detectable mercury. Although not required by regulatory agencies for construction materials, a dermal exposure test also revealed no detectable mercury levels.

"Simple construction as a whole can best be achieved when contractors and clients use resources more efficiently at every stage of construction in order to reduce the amount of waste produced to the barest minimum."- Kamil Mu'azu